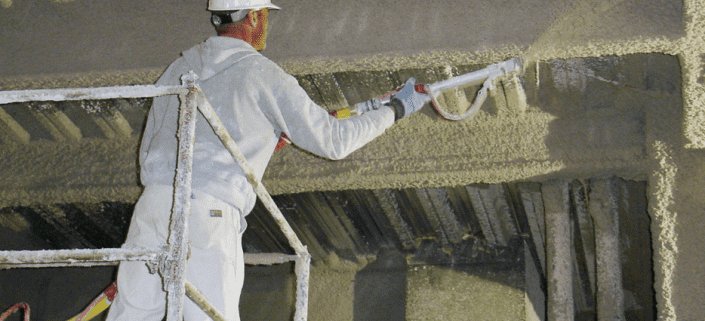

When you first begin a concrete pouring business, or take on work as a general contractor that requires you to pour a little concrete at most, a small or portable mixer might be the right option to get you started. However, as your business grows, you might want to upgrade to a better mixer to allow you to take on more jobs and give better results to your clients. With a better-quality mixer, you can create an even pour of smooth concrete for driveways, walkways, building foundations, swimming pools, and other crucial parts of any home or business property. A smoother finish typically leaves you with a happier customer that is eager to recommend your work to friends and family. Eventually, you can spend a portion of the profits you make on these larger jobs to get the Best Marshalltown concrete mixer and expand your business even more.

Selecting the Best Marshalltown concrete mixer for You

This Marshalltown concrete mixer buying guide will help you determine the right kind of equipment for your growing operation. Whether you work exclusively in concrete, or want to expand the offerings of a remodeling or outdoor contracting business, selecting a mixer that incorporates everything you need at a price point you can afford is important to ensure you recoup your investment in this equipment. As you consider what kind of mixer is right for your operation, there are a few questions you’ll need to address, including:

- Batch or Drum: There are two basic kinds of concrete mixers in use on construction sites around the world. While batch mixers produce batches one at a time, drum mixers can be continuous, meaning they discharge the concrete mix the whole time they are turned on. Which one you choose can be a matter of personal preference or it can be related to how much concrete work you foresee doing. If concrete is not your main line of work, a batch mixer may be all you need to make a limited amount of concrete.

- Gas or electric: With an electric mixer, you’ll need a generator or a plug inside the structure to access the power needed to operate the equipment on site. Gas powered mixers can be more portable, but with the cost of gas rising in many parts of the country, buying gas to operate the mixer can cut into your profits.

- Mixing pattern: The way concrete is mixed impacts the overall smoothness and finish of the surface you lay, so having a mixer that uses a more complex pattern results in a better finish. For example, the Marshalltown concrete mixer uses a quad mixing system to give a more consistent mix and result. The mixer uses a four-piece, replaceable paddle and blade combination to create four different mixing patterns. With two rubber paddles and two made from metal, the concrete gets mixed through a range of approaches, leaving it thoroughly mixed and smooth as silk when it comes out of the mixer.

- Type of brakes: Choose from hand or foot brakes to suit the way you prefer to work or the approach you find to be the most efficient.

- American or Foreign Made: While some contractors prefer to go with an American made product as it can be more durable and long-lasting, others like a product made overseas that is typically less expensive. As you make this choice, remember that cheaper isn’t always better, especially when it comes to equipment that helps you run your business. While a product made in China may cost less initially, it can break down quickly, leading you to spend more on repairs in the long run.

- Budget: The cost of a concrete mixer can range based on the size and brand. If your budget is limited, you can look for a used mixer that is still in good shape.

If you are shopping for the Best Marshalltown concrete mixer to help take your contracting business to the next level of success, let PDQuipment help. With distribution and service centers in Chicago, Houston, Portland, and Fort Myers, we can get the equipment you need to your location quickly. We are dedicated to providing the best deals on equipment, parts, and more to contractors in the United States and even across the world.