The Graco Big Rig Gas Hydraulic Sprayer has many state of the art features that make it the top choice for professionals.

The Graco Big Rig Gas Hydraulic Sprayer is a high-performance, versatile machine that can handle any number of different spraying applications. It is perfect for use in a wide variety of industries, including construction, agriculture, automotive and more. The Big Rig Gas Hydraulic Sprayer is equipped with an exclusive QuikChange Lower, which makes it easy to customize the machine for each specific job. It also features a durable hydraulic cooling system and a high capacity pump that are designed for long-term use.

Benefits of Graco Big Rig Gas Hydraulic Sprayer

It is equipped with an exclusive QuikChange Lower, which allows the user to easily customize the sprayer for each coating. This feature eliminates the need to purchase additional rigs.

The Big Rig also has a Heavy-Duty Graco Hydraulic System that is faster and more responsive than other changeovers on the market.

Additionally, it comes with a Honda Power engine that delivers maximum performance, making it perfect for even the most challenging projects.

A Heavy Duty Cooling System ensures that the Big Rig can handle even the most demanding jobs, while an Xtreme Pump provides the power and durability that professionals need.

The Heavy Duty Hydraulic System is perfect for any challenging project, while the Xtreme Pump provides the power and durability that professionals need.

The Graco Big Rig Gas Hydraulic Sprayer is the perfect choice for any professional who needs maximum performance and unmatched versatility.

Graco Big Rig Gas Hydraulic Sprayer buying guide

When it comes to choosing a gas hydraulic sprayer, there are a few things you need to consider in order to make sure you’re getting the best possible product for your needs. Here are some tips to help you choose the right gas hydraulic sprayer for your needs:

1. First and foremost, you need to decide what kind of project you’ll be using the sprayer for. Whether you’re looking to use it for commercial or industrial purposes, or simply need something for around the home, this will help narrow down your choices and ensure you get the right product.

2. Once you know what kind of project you’ll be undertaking, take a look at the different features each type of sprayer offers. Some models may be better suited for certain tasks than others, so it’s important to find one that has the specific features you need.

3. Another important consideration is the size of the project you’ll be working on. If you’re only going to be using the sprayer for small projects, then a handheld model might be all you need. However, if you’re planning on tackling larger jobs, then a backpack or trolley model would be a better option.

4. When it comes to price, gas hydraulic sprayers can range from relatively inexpensive to quite expensive, depending on the features and size of the unit. As with anything else, it’s important to set a budget before shopping so that you don’t overspend on something you may not need.

5. Finally, take some time to read online reviews of gas hydraulic sprayers before making your final decision. This will give you a good idea of what other users think of the different models on the market, and help you choose the one that’s right for you.

The most powerful hydraulic sprayer in the industry. For 30 years, contractors have turned to the GH line of gas hydraulic sprayers when they needed maximum performance and unmatched versatility. The tradition continues with the all-new line of GH Big Rig sprayers. Equipped with exclusive QuikChange Lowers, each Big Rig sprayer can easily be customized for each coating, eliminating the need to purchase additional rigs.

Finally, the large diameter siphon hose makes it easy to clean and maintain, making it a top choice for those who want a powerful and versatile sprayer.

Benefits of a Gas Hydraulic Sprayer

There are many benefits of choosing a gas hydraulic sprayer over an airless or traditional pump sprayer. Some of these benefits include:

Benefits of Graco Big Rig Gas Hydraulic Sprayer

- Higher flow rates for faster coverage

- Work faster and with less effort

- Quieter operation

- No need for an expensive air compressor

- Easy to use and maintain

- Ideal for a variety of applications, from high pressure for long hose runs to hard-to-atomize materials.

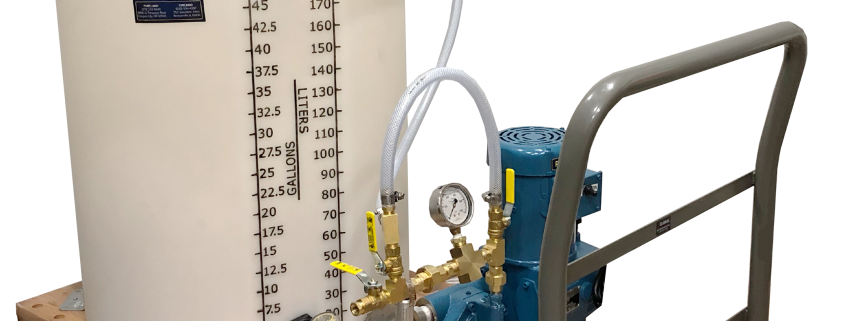

In terms of commercial construction projects, the issue of fireproofing is critical. One way a company will apply fireproofing material is by injecting it. In order to accomplish this feat correctly, you need the assistance of an alum injection pump. These pumps allow the contractor to apply in-line or alum materials to structures while saving time and correctly applying the mixture. Consider this alum injection fireproofing pump buying guide to help you determine if purchasing a pump is a good investment and how to get a great product. Let the experts at PDQuipment provide you with high-quality products for your project needs.

Alum Injection Fireproofing Pump Buying Guide

There are a few things to consider when buying an alum injection fireproofing system. First, you’ll want to choose a reputable product that has been tested and approved by contractors over the years and shown to provide smooth performance. It’s common to select a system that underperforms and fails to apply the material correctly. These are usually the lowest-priced options. If the system doesn’t correctly use the material, it will need to be removed, wasting time and money.

Features of the Alum Injection Pumps

These pumps have a supply tank of approximately 50 gallons and are metered to apply the layer according to the manufacturer’s specifications. The mixture is pressurized and then forced through the hose or material line. It’s sprayed through a one-way valve, so it doesn’t seep into the unused materials in the pump. The person applying the material can easily adjust the amount being dispersed from the pump.

One facet of the pump selection process is convenience and portability. If you have a large job, you’ll want a larger pump to keep up with the volume of work. If you don’t have a large enough pump, you’ll lose valuable time, and the pump will likely wear out faster.

You’ll also want to consider the scope of the job or jobs in question. The height and distance of the project come into play when making your selection. Make sure you also choose the pump that is designed for the specific material you are spraying. Make sure your pump also has a good power supply source on site. In other words, make sure you’ll be able to power the pump on the project without running a generator or having a direct power supply.

Advantages

The advantages of alum injection fireproofing pumps are many. They allow you to provide a barrier of safety from fire for new construction and remodeled areas of a structure. When you invest in a pump, you’ll be able to get more bids and offer your clients more options. This feature is essential for companies and contractors providing a wide range of services to clients.

Get Your Parts From a Reputable Source

You’ll not only need your alum injection pump, but you’ll also need a reliable source for all of the parts and equipment pieces necessary to use the alum injection fireproofing pump. Some parts required can include the following.

- PSI check valve

- T-line strainer

- Shut off valve

- In-line injection module

- Plumbing assembly

- Hose couplings

- Diaphragm

Having quick access from your retailer is essential to ensure you get the right parts for the job in a short time. When you work with the experts at PDQuipment, they’ll ensure you get the right parts for your injector to ensure your business flow is smooth and you’re not stuck waiting for essential pieces to arrive for projects. Reliable service and equipment are important for anyone with construction projects in the works.

A Quality Investment

If you’re currently offering fireproof for new construction or remodeling projects, you’ll need to have the right equipment on hand. Investing in alum injection pumps is a sound investment that ensures you get more jobs. This type of equipment is essential for staying competitive in the construction and remodeling industry. Consider the information in this alum injection fireproofing pump buying guide to help you make the right decision. If you need more assistance, you can contact the experts PDQuipment to ensure you get the right products for your projects. Check out the website today to see all of their products and options for alum injection fireproofing pumps and get the best quality for the money.

Individuals interested in purchasing either stucco or an EIFS mixer should know some in-depth details to ensure they choose the correct mixer for the job. These mixers are responsible for ensuring that the compounds or mixtures arrive at the proper consistency and provide the power and options to do the job. Keep reading to learn more about which machine is ideal for which needs and how to get the best type of machine for your needs. Check out the selection from PDQuipment to find out more and see their wide range of options.

What is EIFS?

EIFS is thermal insulation mixed and then applied to the exterior of a building. It also offers a decorative quality and protects the structure. It’s also ideal for waterproofing when used with other materials. EIFS is also used extensively to create a barrier to making homes and businesses more energy efficient. To correctly mix and apply this material, you need a mixer designed to provide the proper turbulence and consistency.

What is Stucco?

Stucco is an exterior application material made from water, binders, and aggregates. It’s similar to concrete but uses different materials and has an attractive aesthetic appearance. One distinct difference in the mixture is the addition of lime. This highly porous substance allows for airflow and moisture evaporation. The outer layer is relatively thin and makes a good home coating to create a unique and durable finish. The standard application thickness is approximately one inch.

Choosing a Stucco or EIFS Mixer

A few types of mixers are available for sale by the most reputable construction materials retailers. The most common is EIFS mixers or stucco mixers. There are a few notable differences to consider to ensure you make the right choice for your construction project’s needs. One aspect to consider is the brand offerings. The best choice is usually the most highly rated or popular in the market. It’s usually an option with a good warranty and a few standout features.

Consider the advantages of stucco and EIFS mixers. One particular feature is the range of mixing speed options and attachments. When you’re on the job site, you want to ensure you have a few speed options to help you get the right consistency. You also need mixer attachments that can adequately blend the materials and keep them constantly agitated to prevent the setting and ensure you get rid of all the lumps in the materials.

Before choosing a brand, it’s a good idea to compare those findings with your budget and learn more about the advantages of stucco and EIFS mixers. It’s essential to remember that making a good choice by selecting a durable and reliable mixer rather than the lowest price will ensure you don’t have to purchase another for some time.

Differences

There are some differences to know about when it comes to the motor: the advantages of stucco and EIFS mixers for sale. There are some which feature a mechanical drive. These machines are ideal for those who want the most power for the job. They offer an effortless design and portability.

The electric type is best for smaller loads where you don’t need much machine portability. These mixers offer the best value and are ideal for private jobs.

The mechanical gearbox drive erosion has a drive-system preference and delivers plenty of horsepowers to get the job done. This version doesn’t require shaft maintenance or greasing.

Finally, the hydraulic mixer is spring-loaded and doesn’t require much maintenance. There’s no greasing necessary, and the engine is designed for high-volume use.

Benefits of Stucco and EIFS Mixers

The advantages of stucco mixers and EIFS mixers are that they allow you to continuously mix your materials to ensure you get a smooth mix and the mixture doesn’t set too quickly. Many versions are portable except the electric, allowing you to easily move the mixture from one spot to another while keeping the consistency ideal.

If you’re planning on undertaking any new stucco or EIFS projects, be it private or for contracted jobs, you’ll want to invest in the best machines to get the job done. Check out the wide range of options that PDQuipment offers today and get the highest quality products from a reputable company with plenty of products and top customer service. Check out the website today to see their wide assortment of mixers.

When you are laying a floor, you surely want the process to be less time-consuming and labor intensive. And you’ll definitely want to ensure less waste.

The answer to all of these considerations is the Portamix Hippo mixer.

Just one look at the specs and reports on this tool will tell you that it has been designed to offer solutions to every aspect of the process of laying a floor. The aim of the tool is to mix and pour a flooring compound consistently. And to produce a floor of the highest quality.

Ease of operation

The Portamix Mega Hippo is a very efficient tool that is designed to mix, transport and pour any flooring compound. It can be operated easily by one person. This means, when you buy one, you will not have any more need for teams working hard at mixing, transporting and pouring the flooring compound. With the Portamix Mega Hippo, one person can handle and do all three things.

The Portamix Mega Hippo is so efficiently designed and constructed that the person operating it can mix up to 6 bags of compound. They can then use the tool to move what may be up to 440 lbs (200kg) of mix to the correct position. Finally, they can pour and spread the compound where necessary.

Efficiency of design and construction

Every aspect of the Portamix Mega Hippo has been designed and constructed for efficiency.

It is very maneuverable and has a good functional layout. The design and efficiency of the trolley and cradle let you pour and spread the compound simultaneously. This means no multi-stage pours, which then means time saved.

Buying a Portamix Hippo will save you money in the long term and make it a worthwhile investment.

The helix in the Hippo is designed to mix the compound very smoothly, while using a low RPM. This reduces strain on the motor, which means a longer life. The compound is mixed and blended thoroughly, with little or no mess. There will thus be far less waste of material.

Because every feature is so well designed, the Hippo will reduce labor costs. It also ensures that the work is less strenuous. A single worker can keep working for longer, meaning less down time.

When working with flooring compounds, dust is always a problem. There is a dust extraction port on the Portamix Mega Hippo, which reduces this hazard when it is operating.

Other advantages

Some of the other advantages to take note of when buying a Portamix Mega Hippo are:

- You can mix a wide range of compounds in the Hippo, including cement screeds, overlay, epoxies, sealants, resin and grouts.

- When you are working on technical flooring, this is an essential tool to use.

- It is easy to clean the Hippo, no matter what compound has been used.

- This tool will change profit margins and the quality of the finished floor.

- Every aspect is of such quality that the unit will withstand the environment of a construction site.

Some specific specs

The Portamix Mega Hippo has a bowl with a capacity of 22.5 gallons/352 lbs (85 liters/160 kg) when the water and compound are mixed together.

The motor is 2 speeds and is RCD protected, which will protect against any risk of electricity malfunction.

The unit weighs only 15 lbs (6.9 kgs), which is very light to manage.

Support

When you go about buying a Portamix Mega Hippo, there is plenty of support available. You can download the Brochure and the User Manual.

The Brochure presents all the elements of the tool, as well as details about how to use it and what features should be applied when.

The User Manual gives details of all aspects of the unit and of any possible precautions to be taken when using it. How the Hippo functions is clearly outlined and you are given some hints to take note of when you use it to lay flooring. These include the recommendation that the dry ingredients must be added slowly. You are also reminded to follow instructions carefully and make sure to keep the helix totally under the water.

How to buy the Portamix Mega Hippo

If you have any thoughts about buying a Portamix Mega Hippo, then contact PDQquipment.

At PDQ, for any requirement in the building industry, You Need It, We Get It.

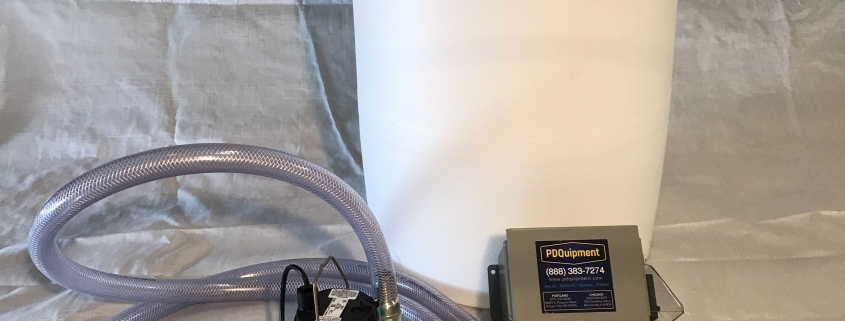

What is the Mortar Water Batching System?

The Mortar Water Batching System is a simple and accurate way to measure water for your mortar batches. It consists of a water tank, a pump, and a timer. Just set the timer and press the button – the system will automatically dispense the amount of water needed for your batch. The system can be used with any size of a mortar mixer.

PDQuipment carries the best water batching system for your needs. We have systems that can be used with electric or gas mortar mixers. Our systems are made with high-quality materials, and we are available to answer any questions about maintenance and repairs.

Why Use a Mortar Water Batching System?

There are many benefits to using a Mortar Water Batching System:

– Simplify the water measuring operation for your labor

– Big time saver and easy to use

– Save money and be more accurate. You will also save time. Our best water batching system will save up to 25% of your water usage

– Get a consistent mix every time

– Reduce the amount of waste you produce

– Eliminate waste and inconsistency

– Ensure the best results by using clean, fresh water in your mortar mix

How Does the Mortar Water Batching System Work?

Our best water batching system is straightforward to use. Just set the timer and press the button – the system will automatically dispense the amount of water needed for your batch. Add it to your water usage routine to improve performance and save resources!

Always use clean, fresh water in your mortar mix for best results. If using city water, we recommend using a filter to remove any chlorine or other chemicals which can damage the pump or other parts of the system. A simple carbon filter like those used on fish tanks will work well and only needs to be replaced every few months.

What Are the Parts of the Mortar Water Batching System?

The Mortar Water Batching System consists of a water tank, pump, and timer.

How Often Should I Calibrate My Mortar Water Batching System?

We recommend calibrating your system before each use to ensure accuracy. This only takes a few minutes and only needs to be done once per day.

To calibrate, simply put a timer on 5 gallons and see how long it takes to fill. This will give you a good idea of your flow rate for that day.

How Do I Clean the Mortar Water Batching System?

It is best practice to clean the system after each use. Water batching systems should be flushed with clean water after each use. A small amount of dish soap can be used to help remove any mortar residue.

Can I Use the Mortar Water Batching System with Any Mortar Mixer?

Yes, the system can be used with any size mortar mixer.

Do I Need a Filter for My Mortar Water Batching System?

If using city water, we recommend using a filter to remove any chlorine or other chemicals which can damage the pump or other parts of the system. A simple carbon filter like those used on fish tanks will work well and only needs to be replaced every few months.

How Much Water Does the Mortar Water Batching System Pump?

The water pump is approximately 1/2 gallon per second. However it will vary with wear, voltage, and other variables. It is best practice to calibrate each time you stage. Using the gallon markers on the tank, you can put a timer on 5 gallons and see how long it takes to fill. This will give you a good idea of your flow rate for that day. Water batching systems should be flushed with clean water after each use.

About the Timer on the Mortar Water Batching System

The timer is very easy to set. Just select the amount of time you need and press the button. These water batching systems will automatically dispense the exact amount of water needed for your batch.

Please contact us for more information on the best water batching system for your needs. We are happy to answer any questions you may have about our products or services. We have decades of experience serving the community!

Buying the right cement mixer requires you to have some key pieces of information about your future projects and job-site needs. If you plan to use a drum mixer, it’s essential to know that it is the best fit for your company or business endeavors to avoid wasting money or purchasing the wrong type of mixer. Keep reading to learn more about drum mortar mixers, and use these key points to help you decide if it’s the right option.

What is a Steel Drum Mortar Mixer?

A drum mixer uses a large container or drum attached to a mechanism that turns the drum to mix the contents, which is primarily used for concrete or cement. It has a double conical frustum shape for the drum portion and also has a set of blades inside that are used to mix the ingredients inserted inside the drum. These types of mixers are ideal for jobs requiring you to mix large batches of aggregate. They are also the correct choice for creating high liquid content mixtures. For thicker mixtures such as mortar, you may need to have some manual intervention if you plan to use a drum mixer.

Mortar mixers are designed specifically for special sand-based mixes for brick and stucco. These types of mixers are designed especially for a thicker mixture with less liquid and a stiffer consistency. These mixers create wear and tear on mixing paddles unless you purchase a drum mortar mixer designed for industrial use.

However, you can purchase a steel drum mortar mixer that gives you the best of both options. It’s designed to handle thinner and thicker mixtures without the wear and tear of a smaller non-drum version of a mortar mixer. You get more use out of it and can depend on them for much longer, which is handy if you plan to use it frequently. Going this route saves time and money on purchasing two separate units to do the same functions.

Shop Steel Drum Mortar Mixers

When you shop for a steel drum mortar mixer, you’ll likely have a few different options to consider. You need to weigh the benefits/costs to make the right choice for your needs and budget. While it may seem like a better option to save money, sometimes you need to replace the mixer more often if you make your selection based on cost alone.

There are some big differences between these two options. Those with smaller jobs or jobs close to a power source may want to choose the electrically-powered version. One reason is that it requires much less maintenance, and the other is the price point. Alternatively, the gas-powered version allows your crew to use it without an available electricity source and can handle more heavy-duty jobs. However, these models are usually more expensive. They require much more maintenance to keep them running smoothly. Still, They may actually be more beneficial and economical in the long run by avoiding having to replace them with a new model sooner.

It’s essential to take the time to analyze how often you plan to use this piece of equipment and which projects you’ll need to use it for, and whether it’s for a personal project or commercial use.

Buying Your Steel Drum Mixture From a Reputable Source

Another important consideration when purchasing steel drum mortar mixers is the seller and their reputation for carrying quality products that are dependable and reasonably priced. Additionally, you’ll want to ensure you get the best customer service and access to representatives who can answer questions and provide support for you before, during, and after the sale. At PDQuipment, our team of professionals is committed to providing the best equipment available for various projects and purposes. To get started, shop steel drum mortar mixers to compare options and gather information about currently available models.

There are details about each product and brief descriptions of its attributes and features. To learn more, reach out directly to the sales team, who will be happy to provide any information available to help you make the right choice. Get the tools you need to complete projects successfully and offer faster, more efficient methods for mixing mortar for current and future needs.

A Big Rig Texture Machine Drywall pump can help you complete your construction projects by installing drywall fast and efficiently. Speed and ease are the greatest benefits of drywall texture pump. If your construction crew is in the market for one of these texture machines, it is essential to do your research. Not every Big Rig Texture Machine Drywall pump is the same, and there are many types on the market. Learning about the various types of machines on the market will help you learn some of the differences between the machines, allowing you to hone in on the one that makes the most sense for your company. Paying attention to the Benefits of Drywall texture pumps is also important. Here is a buying guide that will help you select the right big rig texture machine.

Gas & Diesel

A gas & diesel big rig texture machine is a truck-mounted machine that operates using gas or diesel fuel. This is perfect if you are working in areas where there may not yet be electricity for you to tap in, such as new homes. Gas and diesel pumps can be towed to a location in a truck bed or on a flatbed. This model comes in various sizes ranging from 150-gallon to 420-gallon tank sizes. The models are also equipped with engines that range from 20 horsepower to 50 horsepower, depending on the various tank sizes. This type of equipment features an electric pump switch, a Binks gun, a longer hose set, a split tank and a butterfly valve pump.

Electric

An electric big rig texture machine is powered by electricity. This type of machine needs to be plugged into an electrical outlet to operate. As such, this type of machine is best suited for those who do work in homes or commercial spaces that already have electricity in place. Just like a gas and diesel pump, an electric pump can be transported to the job site on a flatbed trailer or in the bed of a construction truck. This type of big rig texture machine features tanks that range from 100 gallons to 350 gallons in size. The unit also features electric motors that may or may not have compressors, depending on the size of the tank. On this type of model, you do get a Binks gun and a longer hose set, but you will have to upgrade to an electric pump switch and a butterfly valve pump.

Skid

A skid big rig texture machine is a texture machine that is typically housed inside of a trailer. It can be either gas-powered or electric. The reason the machine is housed inside of a trailer is typically due to weather elements. If you live in an area that has freezing temperatures, you may wish to store the equipment inside of a trailer so that the weather does not destroy the machine itself or freeze the material that is being sprayed inside the home on the drywall. Skid-mounted big rig texture machines generally range in size, varying from 150 gallons to 500 gallons. The machines also all feature 20 to 50-horsepower engines and compressors. Skid big rig texture machines have many advantages, including being easier to clean and maintain, as they are not exposed to weather elements. However, they typically cost more.

Truck Mount

A truck mount big rig texture machine is the most expensive option available. It is mounted to a truck, meaning you have to purchase a truck with the mount. However, truck mount machines are also much larger and have a lot more power than their small gas and electric trailer counterparts. This type of equipment is ideal for those who handle large drywall construction projects, such as commercial projects. Most truck mount equipment is diesel-powered, but it may come in gas-powered versions as well. Truck mount models can also be customized specifically to your needs, including the engine and amount of horsepower you desire. This makes this a great option for someone who wants a customized big rig texture machine.

When you are in the market for a Big Rig Texture Machine Drywall pump, it is important to understand that not every model of pump available is the same. There are many differences between the various types of pumps available, including how they are powered and how they can be towed to the site. Four of the most common models of pumps include gas and diesel-powered pumps, electric-powered pumps, skid pumps and truck mount pumps. Learning about some of the differences and then taking the time to learn about the specific Benefits of Drywall texture pumps associated with various models can help you hone in on the model that is best suited for your company. This is the best way to find a pump that will meet your needs both now and well into the future.

The Kaeser Mobilair™ M82 is a versatile, high-performance portable compressor that is perfect for various applications, including construction, mining, and general industrial use.

When choosing a portable air compressor, it is essential to consider your specific needs to find the best match. The Kaeser Mobilair™ M82 is an excellent choice for those who need a reliable and powerful machine that can handle even the most strenuous tasks. With its robust design and array of features, the M82 is sure to provide years of trouble-free service.

This Kaeser M82 Portable Compressor Buying guide highlights all of the best features that the machine has.

It uses a Sigma Profile rotary screw airend. So, it gives you more air with a lower horsepower. This feature is especially useful in construction and mining applications where there is a need for a lot of air.

Lowered Emissions

The machine is designed to have lower emissions. It adheres to Tier 4 Final standards. So, you can be sure that it is environment-friendly.

Less Maintenance

The machine has been designed for easy maintenance. It has easily accessible service points. So, you can save time and money on maintenance. This Kaeser M82 Portable Compressor Buying guide recommends having your machine inspected regularly.

Large fuel tank

The fuel tank holds up to 37 gallons. This allows you to use it continuously for up to 10 hours. Save time on the job site by not having to stop and refueling often.

Anti frost valve

The anti-frost valve allows you to work in even harsh weather conditions. This Kaeser M82 Portable Compressor Buying guide notes it’s a hardy machine against many weather conditions.

Multiple Air pressure options

You can choose from 100 psig, 145 psig, 175 psig, or 205 psig. This gives you the flexibility to use the machine for a variety of applications.

Smart Electronic Controller

The Sigma Control Smart electronic controller is standard on the M82. This gives you greater control over the machine. The controller has a clear and easy-to-read display. It also has an integrated pressure switch and thermal overload protection.

Powder-coated Steel Cabinet

The cabinet is made of powder-coated steel. This makes the machine durable and able to withstand even the most rugged conditions.

Super soundproofed

The M82 has been designed for quiet operation. It has a sound level of only 78 dB(A) from a distance of 27 feet. This means that it will not be a disturbance on the job site.

Height adjustable hitch with rigid tow bar

The hitch is height adjustable. This allows you to tow the machine behind a variety of vehicles. In addition, the tow bar is rigid for added stability.

Lifting eye

The machine has lifting eyelets. This makes it easy to transport.

Included cooling feature

The machine comes with an integrated cooling fan. This helps to keep the machine running at peak performance.

Optional 5-year warranty

You can choose to extend the warranty to 5 years. This gives you added peace of mind knowing that your investment is protected.

Gullwing Doors provide easy access

The gullwing doors provide easy access to all service points. This makes it easy to keep the machine running at peak performance.

Heavy-duty bumpers and lighting kit

The machine comes with heavy-duty bumpers and a lighting kit. This makes it easy to use in even the most challenging conditions.

Optional aftercooler package

The aftercooler package is an optional extra. It helps to cool the air before it enters the tank. This helps to extend the life of the machine.

High capacity cold start battery

The machine comes with a high-capacity cold start battery. This helps to ensure that the machine is always ready to use.

Optional skid mount package

The skid mount package is an optional extra. However, it helps to make the machine even more portable.

Three 3/4 Chicago style fittings and one 1-1/2″ NPT connection port

The machine has three 3/4″ Chicago style fittings and one 1-1/2″ NPT connection port. This gives you the flexibility to use the machine for a variety of applications.

Fold-down handle

The Kaeser Mobilair™ M82 is a great choice for those who need a reliable and powerful portable air compressor. With its robust design and array of features, the M82 is sure to provide years of trouble-free service. If you would like more information or how to purchase, please contact PDQuipment.