Investing in a concrete mixer can boost your construction business efficiency. Remember, concrete is a must-have in building and renovation projects, whether you are constructing a basement or a driveway. Essentially, a concrete mixer mixes water, cement, and aggregate that form concrete for construction work. For large construction, mixers provide an efficient alternative to manual mixing and offer consistent concrete.

5 Crucial Considerations when buying a concrete mixer

With the myriad of brands and types of mixers in the market, you must wisely choose a suitable mixer. Below are some essential things you should consider when buying a concrete mixer for a construction job. Let’s delve right in.

1. Power supply

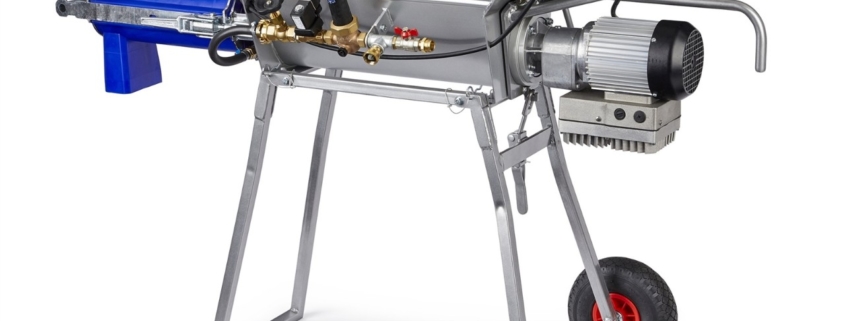

There are two main cement mixer options: fuel and electric mixer. The type of power supply you need will determine the right mixer for the job. In other words, You should ensure you have a power supply when purchasing an electric unit. On the other hand, a petrol engine allows you to work independently of the electric power supply. Typically, Fuel engines are robust, durable, and mix relatively bigger volumes of concrete. However, they are more decadent and less environmentally friendly compared to electric machines. Diesel Fuel machines are also available in the market. The best advantage of fuel mixers is that they work in remote areas with no power supply.

2. Performance and capacity

This is a pretty straightforward point. If you want to boost construction work productivity, you should invest in a cement mixer that offers astounding performance. For instance, large projects require large units for better and faster performance. Large mining machines churn out large volumes of concrete hence save time. On the same note, it is imperative that you consider the motor power rating of the machine. Powerful Concrete mixture machine mixes all concrete ingredients properly. For instance, a mixture machine that features a 1500 RPM motor offers the top results. In other words, it rotates 3000 times in 2 min hence delivering consistent concrete. Similarly, a high motor rating like ¾ HP has relatively better performance.

3. Size

The ideal size of a mixture depends on the type of job. A small compact mixer is easy to move and occupies a small space in a job site and garage. For small jobs, a small concrete mixer will get the job done. On the other hand, a concrete mixture machine with massive capacity comes in handy if you plan to mix a lot of concrete at once. Typically, the larger mixture machines have a capacity of 6 cubic feet. To put this into perspective, a drum with a 3.5-foot cubic capacity holds about 80 pounds of concrete.

4. Durability

When buying a mixer, you should go fora robust machine that will withstand the tests of time. This means that the tank and frame should be strong and durable. In other words, it reduces the risk of the mixer falling when placed on rough terrain. Remember, construction tools experience a lot of wear and tear on the job site.

Build quality is a paramount consideration. Luckily, some options come with an extended warranty spanning up to two years. The good news is that electric motor mixtures are designed with IP45 AND 1P55 for water resistance. They protect damage from the water used in concrete and hence, boost durability.

Steel and plastics are the most common materials used in manufacturing concrete mixer drums.

Plastic or poly drums are lightweight and easier to clean. However, abrasion from concrete causes faster wear. On the other hand, steel drums last long. However, they tend to be heavier and harder and require a more powerful motor. What’s more, steel machines have long durability compared to aluminum ones.

5. Portability

Depending on the nature of your construction job, you can opt for stationary mixer mobile units. Stationary mixers are a perfect choice if you prepare concrete on one job site. However, if you move between several job sites, you should consider choosing an on-site mobile unit. For sturdier and larger machines, you will want to consider the trailer-mounted mixer. The point is that portable concrete mixers are generally lightweight and smaller and can be moved around with ease.

Some Concrete mixers are fitted with a wheelbarrow. Ideally, the wheel should be strong enough to withstand the construction terrain. Moreover, heavy-duty mixers require thick and sturdy wheels for support and stability. The last thing you want is a mixer tipping and pouring the content. For light-duty mixers, pouring content into conventional barrows is easy. Generally, they do not have wheelbarrows.

Choose the Best

The choice of the concrete mixture can affect the output of your construction work. It is prudent that you choose a concrete mixture with the capacity to handle construction work seamlessly. PDQuipment stock a variety of new and used concrete mixers. You can rest assured that you will find a machine that suits your needs. Call them today for a quote.