Key Features to Consider When Selecting Fireproofing Hoses for Industrial Applications

The critical need for reliable fireproofing equipment in industrial settings cannot be understated. A crucial component of fireproofing buildings and structures are fireproofing hoses. Continue reading to discover comprehensive insights into the key features to consider when selecting Industrial fireproofing hoses, especially as they relate to safety, compliance, and reliability.

Understanding Industrial Fireproofing Needs

Before delving into the specifics of fireproofing hoses, it’s essential to recognize the unique fire hazards prevalent in industrial settings. The potential risks and complexities in these environments demand strict compliance with safety regulations and standards.

Material and Construction

The durability and resistance of fireproofing hoses ensure the effectiveness of the hoses in critical situations. Reinforcement layers within the hose itself adds strength, while coatings and covers protect against abrasion and external factors, enhancing the longevity of fireproofing hoses in challenging industrial environments.

Temperature and Pressure Ratings

Fireproofing hoses must align with the demanding conditions of job sites and industrial settings. Matching pressure ratings to specific application requirements is equally crucial. Rigorous pressure testing, coupled with safety factors, ensures the hoses’ reliability when fireproofing material is being applied to walls.

Size and Length

Selecting the right hose diameter is essential for efficient flow, while determining the appropriate length ensures adequate coverage to complete fireproofing jobs on time and within budget. There are also customization options to consider, which provide industry leaders with various layouts and configurations within industrial facilities.

Compatibility with Fire Suppressants

The effectiveness of fireproofing hoses depends on their compatibility with fire suppressants and extinguishing agents. Resistance to chemical corrosion from suppressants is vital, ensuring the hoses will maintain their integrity without degradation or contamination of the suppressants prior to and during a job.

Fittings and Couplings

Choosing the right hose connections and couplings are also a critical part of ensuring seamless integration with any existing fireproofing equipment. Compatibility and ease of installation and maintenance contribute to the overall efficiency of these working systems.

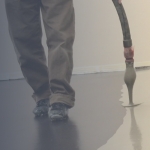

Flexibility and Maneuverability

Assessing the flexibility of fireproofing hoses is vital for ease of handling and storage. Bend radius and kink resistance, coupled with maneuverability in tight or complex industrial settings, ensure that fireproofing hoses can adapt to the diverse challenges presented in industrial environments.

Certification and Compliance

Fireproofing hoses should meet industry standards and certifications such as UL, FM, and NFPA. Ensuring compliance with local and national fire safety regulations is non-negotiable so that safety standards are met. Third-party testing and validation will further affirm the hoses’ reliability and adherence to stringent standards.

Maintenance and Inspection

Establishing a regular inspection and maintenance schedule is crucial for ensuring the ongoing functionality of fireproofing hoses. Proper storage and care, coupled with training personnel in hose maintenance and safety protocols will contribute to the prolonged life and optimal performance of your hoses for years to come.

Cost Considerations

While balancing quality and cost-effectiveness is essential, you should also think beyond the initial costs when buying fireproofing hoses. Factoring in the total cost of ownership, including maintenance expenses, is key since long-term reliability will support more sustainable business practices over time. In other words, it will not serve your business by purchasing the cheapest fireproofing hose on the market because you will get what you pay for.

Supplier Reputation and Support

Researching and selecting reputable fireproofing hose manufacturers that provide technical support and training enhances the user experience. Make sure you look at the supplier’s track record and customer testimonials to give you an idea about the reliability of the hose itself and the customer support they will offer you.

Selecting fireproofing hoses for industrial applications requires a holistic approach. Some of the key features to take note of are its materials, pressure rating, size, fittings, and overall flexibility. Safety, compliance, and reliability should be at the forefront of your mind before you make a final decision.

At PDQuipment, we sell and rent high-quality industrial machinery and equipment to contractors throughout the United States. Click here to view our selection of fireproofing hoses, couplings, and more.